Polyurethane Track: The Ultimate Guide to Modern Sports Surfaces

Introduction

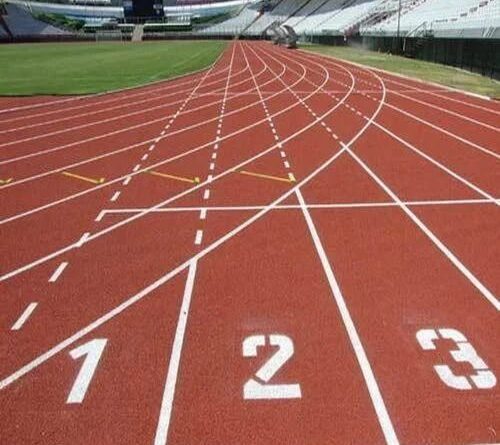

Sports have evolved, and so have the surfaces athletes train and compete on. A major revolution in the athletics world is the polyurethane track. Known for its durability, smooth texture, and superior performance, this modern track surface has become the gold standard for schools, universities, and professional stadiums across the globe.

When it comes to track and field, the right surface can make or break an athlete’s performance. From reducing injury risks to enhancing speed, a polyurethane track provides the ideal blend of comfort, safety, and reliability. Whether you are a sports facility owner, an athlete, or simply curious about the technology behind modern sports infrastructure, this article will give you a complete, easy-to-understand breakdown of polyurethane tracks.

What is a Polyurethane Track?

A polyurethane track is a synthetic sports surface made from layers of polyurethane material combined with rubber granules. This design ensures maximum resilience, shock absorption, and grip. Unlike old cinder or asphalt tracks, polyurethane offers a consistent surface for running, sprinting, and jumping — regardless of weather conditions.

Key Characteristics of Polyurethane Track

- High elasticity – Provides excellent bounce and energy return.

- Non-slip surface – Ensures safety for athletes, even in wet conditions.

- Weather-resistant – Works effectively in heat, cold, and rain.

- Durable design – Lasts for years with proper maintenance.

Types of Polyurethane Tracks

Not all polyurethane tracks are the same. Different facilities choose different types based on budget, usage, and performance requirements.

1. Sandwich System Track

- A base layer of rubber granules topped with polyurethane.

- Affordable and suitable for schools and community stadiums.

2. Full Pour System Track

- A seamless, multi-layered polyurethane structure.

- Preferred for international competitions and professional athletics.

3. Spray Coat System Track

- The most economical option.

- Ideal for training grounds and recreational use.

Benefits of Polyurethane Track

Enhanced Athletic Performance

The elasticity of polyurethane offers superior energy return, helping athletes achieve better speed and endurance.

Injury Prevention

Shock absorption minimizes stress on joints, reducing the risk of sprains and long-term injuries.

Low Maintenance

Polyurethane tracks require minimal upkeep compared to natural or asphalt alternatives.

Longevity

With proper care, these tracks can last over a decade, making them a cost-effective investment.

Installation Process of Polyurethane Track

Installing a polyurethane track requires professional expertise.

Step-by-Step Installation

- Base Preparation – Concrete or asphalt foundation is laid.

- Elastic Layer – Rubber granules mixed with binder applied for cushioning.

- Polyurethane Layers – Multiple coatings create a smooth, resilient surface.

- Line Marking – Precise lanes and event markings are painted.

Maintenance of Polyurethane Track

Regular maintenance extends the life and performance of polyurethane tracks.

Maintenance Tips

- Clean debris and dirt weekly.

- Wash the surface to remove sweat, dust, and oil buildup.

- Inspect for cracks or surface damage annually.

- Restrict spiked shoes outside of events to avoid surface damage.

Polyurethane Track vs. Other Track Surfaces

| Feature | Polyurethane Track | Asphalt Track | Grass Track |

| Durability | 10–15 years | 3–5 years | Seasonal |

| Performance | High | Medium | Low |

| Safety | Excellent | Moderate | Poor |

| Maintenance | Low | High | High |

| Weather Resistance | Excellent | Poor | Poor |

Cost of Polyurethane Track

The cost depends on:

- Track type (Sandwich, Full Pour, Spray Coat).

- Thickness of layers.

- Size of facility.

- Installation region.

On average, polyurethane tracks range between $40 to $80 per square meter, making them a premium yet long-lasting choice.

Global Use of Polyurethane Track

Polyurethane tracks are now standard for Olympic stadiums, World Championship events, universities, and community sports complexes. Their popularity is growing worldwide due to performance benefits and eco-friendly production methods.

Why Choose Polyurethane Track?

- Provides a professional standard surface.

- Enhances athlete confidence and results.

- Offers excellent ROI (Return on Investment).

- Environmentally sustainable with recyclable materials.

Conclusion

The polyurethane track is more than just a running surface — it’s a technological advancement that combines science, performance, and sustainability. From school grounds to Olympic arenas, polyurethane tracks have transformed athletics with their durability, safety, and superior design.

If you’re planning to build or upgrade a sports facility, investing in a polyurethane track is one of the smartest decisions. It ensures long-term performance, athlete safety, and global recognition.

In short, the polyurethane track isn’t just the present of athletics — it’s the future.

FAQs about Polyurethane Track

Q1. How long does a polyurethane track last?

With proper maintenance, it can last 10–15 years.

Q2. Can polyurethane tracks be used in rainy weather?

Yes, they are slip-resistant and safe in wet conditions.

Q3. Is polyurethane track eco-friendly?

Many manufacturers now use recyclable materials, making it an environmentally safe option.

Q4. What is the main difference between a polyurethane and asphalt track?

Polyurethane offers superior performance, durability, and injury prevention compared to asphalt.

Q5. How much does it cost to install a polyurethane track?

Depending on type and size, installation costs range from $40 to $80 per square meter.